The Leader of Tool Tech

Inkok always try to contribute for human society by philosophy of people oriented,Eco-friendly and information management,

- Product

- Online FAQGO

COUPLING

COUPLING

Coupling is a mechanical element connecting the driveshaft and the intermediate shaft, and is used not only by general-purpose motors, but also construction machinery engines with high vibration and shock and also by machine tools with precise control.

JAW COUPLING

JAW Coupling is a feature of small, light and high torque. This unique feature of small size, light weight and high transfer torque effectively improves drive characteristics and reliability. Respond to customer's different environments with different standard elements.

-

Standard Elastomer

- Hardness : 92SHA

- Color : Yellow

- Working Temperature : -40~ + 80˚C

- Instant Heat : 120˚C

-

Standard Elastomer

- Hardness : 98SHA

- Color : Red

- Working Temperature : -40~ + 90˚C

- Instant Heat : 120˚C

-

Standard Elastomer

- Hardness : 98SHA

- Color : Red

- Working Temperature : -40~ + 90˚C

- Instant Heat : 120˚C

DISK COUPLING

Disk coupling is made in a no-backlash. Disks are made of stainless steel with higher strength, greater torsion, compensating for deviations, less resilience, higher hot resistance and no maintenance required.

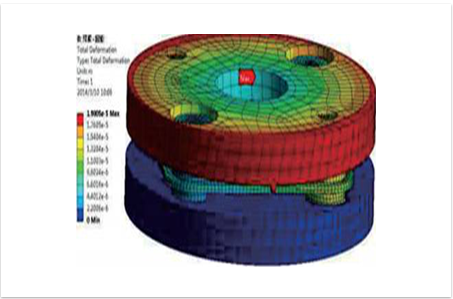

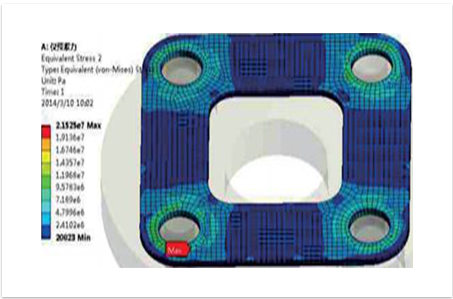

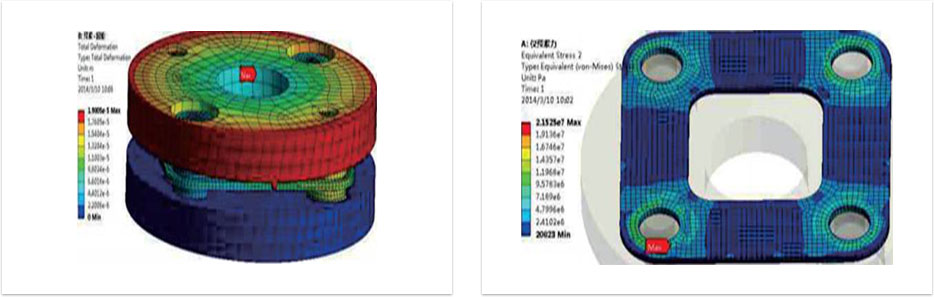

Stainless steel, spring steel is designed with a finite element analysis. This method extracts the special appearance of sources of disk contacts. This enables successful protection from stress concentrations, while retaining coupling and extending the service life.

Machine tool Coupling

Rigid type coupling corresponds to precision machine tool.

Construction coupling

It is resistant to vibration and shock, and is resistant to cold, heat and oil, making it available in harsh environments.