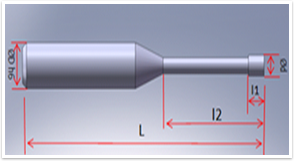

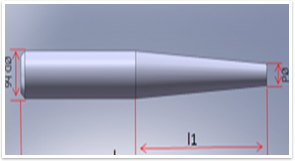

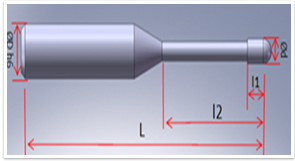

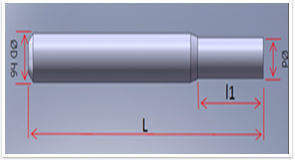

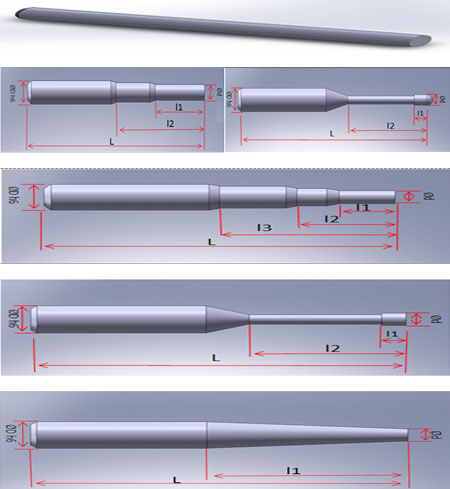

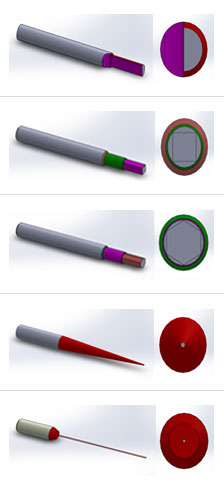

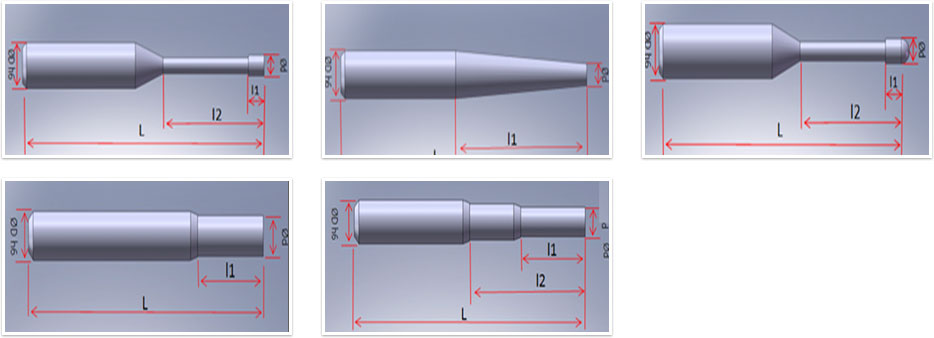

CNC SK-3000 has high precision for step grinding and like below table, it could grind standard and special various shapes.

CATALOGThe Leader of Tool Tech

Inkok always try to contribute for human society by philosophy of people oriented,Eco-friendly and information management,

- Product

- Online FAQGO

Tool Grinding Machine

SK-3000

일반사항

Application

-

Stand shape

-

Special Shape

-

Application

- Cutting tools

Step grinding for Endmill, Drill, ID type drill, Multi steps drill, T-Cutter etc

- Mold pin and punch with precision and various shapes

- Dental Drills

- Cylindrical Grinding

From cylindrical rod, it could be grinded as half square, square, hex,

- Cutting tools

Spcification

- Model name CNC-SK3000

- Maker INKOK Industrial Co., Ltd

- Country Korea

-

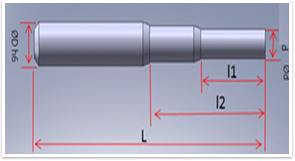

Grinding Range

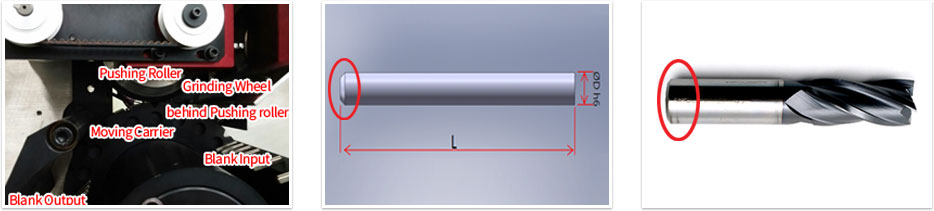

- Diameter : Φ 0.025mm ~ Φ16mm

- Shank : Φ 1.0mm ~ Φ16mm

- Collect : SCHAUBLIN W20

- Length : Max 330mm

-

Auto Loading

- Shank : Φ 1.0mm ~ Φ16mm

- Overall Length : 30mm ~ 300mm

-

Manual Loading

- Shank : Φ 1.0mm ~ Φ20mm

- Overall Length : 30mm ~ 300mm

-

Precision

- Run-out : Under 0.002mm

- Concentricity Tolerance : Under 0.002mm

-

Size

- Width : 1.,800mm

- Length : 2,000mm

- Height : 2,100mm

-

Control

- Fanuc CNC OiT-F, Panel PC

- Programming : Smart Sharp Grinding

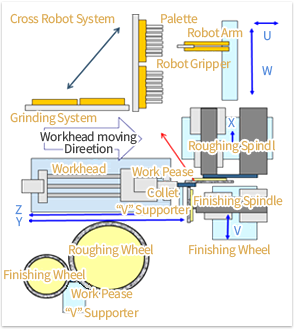

- CNC 5 Axis : Y/Z/X/V/C Axis Grinding Part

- CNC 3 Axis : U/V/W Robot Part

- C Axis : Stroke -> 360 degrees Rotation / Resolution -> 0.0001mm

- Z Axis : Stroke -> 100mm / Resolution -> 0.0001mm

- X Axis : Stroke -> 29mm / Resolution -> 0.0001mm

- Y Axis : Stroke -> 350mm / Resolution -> 0.0001mm

- V Axis : Stroke -> 29mm / Resolution -> 0.0001mm

-

Action

- Roughing Motor : 8.5Kw(11Hp), Belt driven, internal coolant

- Roughing Spindle : Φ 100mm(4” ), Wheel supporter

- Roughing Wheel : Diamond Wheel, Φ 250mm(10”)

- Finishing Motor : 1.4Kw(2Hp), Belt driven, internal coolant

- Finishing Spindle : Φ 100mm(4” ), Wheel supporter

- Finishing Wheel : Diamond Wheel, Φ 150mm(6” )

- Work Head : FANUC SERVO MOTOR + SPINDLE

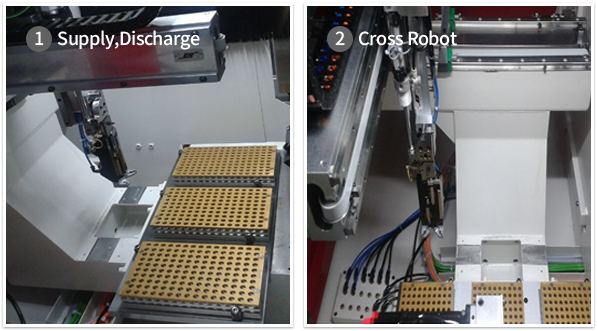

Cassette

- 1. It has automatic loading/unloading

-

system and cassette for auto feeding in a collet so it can make manufacturing to be fast without operator.

- 2. Cross robot has high precision

-

Using linear guide and Fanuc Servo Motor, so that durability and precision are excellent.

- With Cassette, mass work pieces could be manufactured by Robot, so the productivity could be maximum.

- Cassettes are basic option.(Ø1 ~ Ø20)

Fanuc Controller

- Model name : Fanuc CNC 0iT-F, Panel PC

-

- CNC-SK3000 is using Fanuc CNC Controller, and this has the best precision and durability

- CNC-SK3000’s motion is controlled by Fanuc CNC 0iT-F and touch panel PC

- Touch panel Monitor and assembled PC with comfortable user Inter face.

Work Head

-

- Joint Development of Work Head Spindle in Switzerland TDM. Ensure Concentricity of 2 μm or less

- Use of Switzerland SEINEGGER Precision Work Head Motor.

- Use UP(ultra-precision) collet in SCHAUBLIN, from Germany. Run-Out ensures no higher than 2 μm.

- Use of the Z-axis, Y-axis highest-precision LM Guide from the Switzerland STEINMEYER- greater precision and durability.

- Parallel and right angle of the V supporter ensures in 2 μm or less

- The concentricity error of the round bars by the Work Head -Collet – Roller – V supporter ensures no more than 2 μm.

Grinding wheel & Spindle part

-

- Roughing diamond wheel and Finishing diamond wheel can grind both roughing edge and finishing edge at the same time, so that a significantly quicker processing time can be provided by CNC precision control with a higher precision control of 2 μm or less

- Joint development of Roughing spindle, Roughing motor, Finishing spindle, Work head of Switzerland TDM. It guarantees high precision operation Than lower 2 μm

- X, Y Axis of Egis from Switzerland, These are top-grade of LM guide and ball screws with high precision and durability

- There is a re-grinding device for Finishing diamond wheel. It is easy to re-grind the Finishing wheel.

SK-2000

일반사항

Spcification

- Model name CNC-SK2000

- Maker INKOK Industrial Co., Ltd

- Country Korea

-

Grinding Range

- Diameter : Φ 0.025mm ~ Φ16mm

- Shank : Φ 0.025mm ~ Φ16mm

- Collect : SCHAUBLIN W20

- Length : Max 330mm

-

Auto Loading

- Shank : Φ 0.025mm ~ Φ16mm

- Overall Length : 30mm ~ 150mm

-

Manual Loading

- Shank : Φ 1.0mm ~ Φ20mm

- Overall Length : 30mm ~ 300mm

-

Hydraulic element

- An oil tank : 10ℓ(2.6 US Gal.)

- Oil pressure : 12 Bars(174 Psi.)

-

Precision

- Run-out : Under 0.002mm

- Concentricity Tolerance : Under 0.002mm

-

Size

- Width : 1,800mm

- Length : 2,000mm

- Height : 2,000mm

-

Control

- Fanuc CNC OiT-D, Panel PC

- Programming : Smart Sharp Grinding

- CNC 5 Axis : Y/Z/X/V Axis Grinding Part

- CNC 3 Axis : U/V Robot Part

- Z Axis : Stroke -> 100mm / Resolution -> 0.0001mm

- X Axis : Stroke -> 30mm / Resolution -> 0.0001mm

- Y Axis : Stroke -> 350mm / Resolution -> 0.0001mm

- V Axis : Stroke -> 22mm / Resolution -> 0.0001mm

-

Action

- Roughing Motor : 8.5Kw(11Hp), Belt driven, internal coolant

- Roughing Spindle : Φ 100mm(4” ), Wheel supporter

- Roughing Wheel : Diamond Wheel, Φ 250mm(10” )

- Finishing Motor : 1.4Kw(2Hp), Belt driven, internal coolant

- Finishing Spindle : Φ 100mm(4” ), Wheel supporter

- Finishing Wheel : Diamond Wheel, Φ 150mm(6” )

- Work Head : 0.7Kw(1Hp), 300~3000RPM Adjustable

APPLICATIONS SK-2000

Cassette

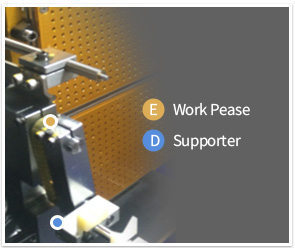

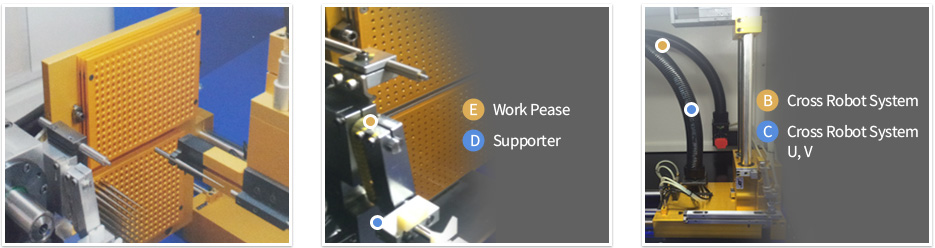

- A It is supplied the palettes for automatic grinding. It is possible to do mass production.

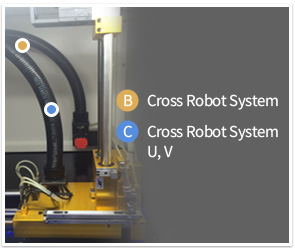

- B C The ball screws are adopted as STEINMEYER of Switzerland. It has higher precision and durability.

- D There is the basket of Work piece for next operation so that the cycle time can be minimized

-

E

- There the Stopper of the work piece, so that the work piece always can place on the correct position and it can drive the precision grinding

- The many work pieces could be put on the pallet and it could be in mass production. And it could make productivity to be increase. The whole size of pallets are supplied basically

Cross Robot System

- The robotics system

-

of CNC-SK2000 does not apply expensive robot arms. The advanced features are included in the original package, not as options. This can also improve your productivity to the furthest.

- Grinding System

-

The machining systemcomprises the work head, which fixes the material to the collet and rotates it, as it is machined using the roughing wheel and the finishing wheel as they perform rough grinding and finish grinding at the same time. This optimizes the processing time of the material and maximize your productivity.

- Parts

-

This process is further supported by Swiss’s TDM spindle, Schaublin collet, Germany’s FAG bearings, Steinmyer ball screw, LM guide, and Japanese Fanuc

- controller

-

ensuring precise machining with 0.0001mm level precision numeric control. The precision level of machining can be set below 0.002mm.

Fanuc Controller

- Model name : Fanuc CNC 0iT-D, Panel PC

-

- CNC-SK2000 is using Fanuc CNC Controller, and this has the best precision and durability.

- CNC-SK2000’s motion is controlled by Fanuc CNC 0iT-D and touch panel PC –Servo.

- Touch panel Monitor, and assembled PC with comfortable user Inter face.

Grinding wheel & Spindle part

-

- Roughing diamond wheel and Finishing diamond wheel can grind both roughing edge and finishing edge at the same time, so that a significantly quicker processing time can be provided by CNC precision control with a higher precision control of 2 μm or less

- Joint development of Roughing spindle, Roughing motor, Finishing spindle, Work head of Switzerland TDM. It guarantees high precision operation with lower 2 μm

- X, Y Axis of Egis from Switzerland, These are top-grade of LM guide and ball screws with high precision and durability

- There is a re-grinding device for Finishing diamond wheel. It is easy to re-grind the Finish wheel.

SK-500

일반사항

Beveling Machines (Chamfering)

- Model Name CNC-SK500

- Usage Chamfering

- Outside Dimension W550mm × D570mm × H500mm

- Weight 125kg

- Power Supply 220V, 60Hz

- Chamfer Angle Variable between 45˚

- Cycle Time Variable range from 2 and 20 second

- Grinding Wheel 1A1, 125 × 20 × 20

- Grinding Motor 0.4Kw, 2860rpm, 220V

- Grinding Range Diamater. 3~20mm(Depending on Drum) Max. 38(32)~195mm long